Welding Expertise You Can Trust

Our AWS-certified welders work closely with engineers and inspectors to ensure that every joint meets your durability and performance requirements for weldments and assemblies. We can help you reduce the need for unnecessary joining hardware and decrease weldment weights, saving money that you can invest elsewhere.

To support this, we have made significant investments in welding and automation technologies, including:

- 155 welding cells (TIG and MIG)

- 18 robotic welding cells

- 9 resistance welding cells: 90 KVA to 200 KVA

- 5 stud welders

- Submerged arc-welder

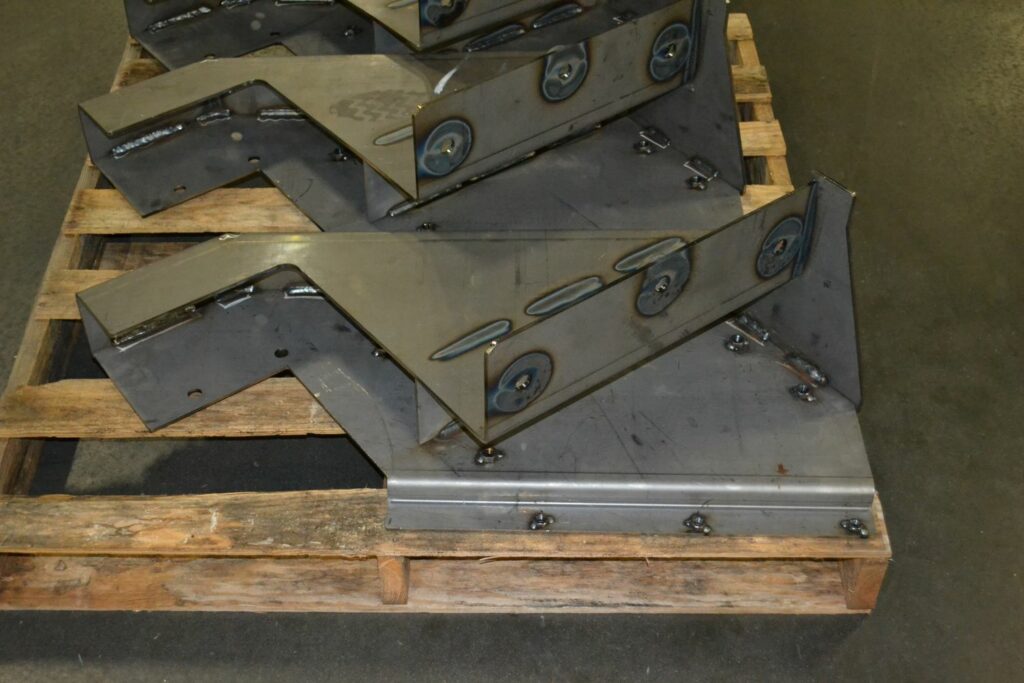

Our Custom Welding Capabilities

The Credentials

Our expert team of engineers, inspectors, and welders hold certifications in ISO and AWS. We work to provide quality parts at the lowest cost.

The Experience

We have over 90 years of experience in quality fabrication, supporting our comprehensive robotic and manual welding capabilities for all grades of steel, aluminum, and stainless steel.

The Capacity

Our facilities in the U.S. and Mexico are purpose-built for even the largest assemblies. With 15 weld positioners, we can handle assemblies from 100 lbs. to 15,000 lbs. (45.36 kg to 6,804 kg), and we’re continuously growing to meet your industry needs.

Your Value-Added Welding Partner

We integrate our qualified welding services with deep contract manufacturing capabilities to deliver value, improve quality, and reduce costs. Contact us to learn how our welding experience can deliver this value to your operations.

Our Welding Benefits Add Up

Improved Quality

Better Equipped

More Value

Accurate Timelines

See What's Possible

Why Standard Iron

OEMs choose Standard Iron for more than just outstanding parts. For 90+ years, we have been a strength in customer supply chains and a seamless extension of their assembly operation. Learn more or start your quote today.