Faster, More Precise Metal Profiling

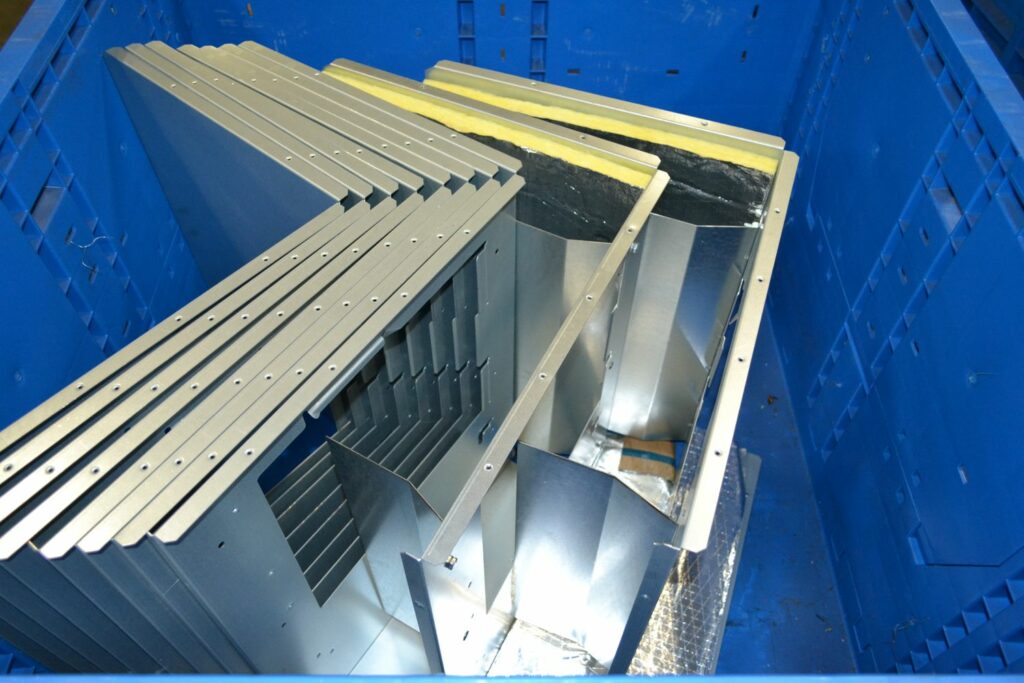

We offer some of the industry’s fastest precision laser, turret, and stamping capabilities to meet the most demanding tolerances for stainless and mild steel parts. Our auto programming and nesting minimize metal scrap with automation features for unattended runs. By integrating these services, we can reduce costs and shorten lead times.

We recently invested $7 million in new equipment for metal profiling and contract manufacturing to improve your product development processes, including:

- 10 fiber optic and CO2 lasers with auto load/unload

- 700,000-plus square feet of profiling and manufacturing capacity

- Stamping capabilities up to 800 Tons

- 4 Amada AE 2510 NT turret presses

Our Metal Profiling Capabilities

Thermal Cutting

We offer auto load/unload lasers with high positional accuracy for a wide range of applications, from steel plates with strict tolerances to delicate prototypes. Our lasers can cut prototype runs up to 1″ thick and production runs up to 5/8” (16mm).

Turret Punching

Our 58-station turret press does the work of seven presses. It can punch up to 1,800 strokes per minute for sheet sizes up to 5’ x 13’ (1.52m x 3.96m) and offers more metal punching and blanking options to reduce welded components.

Steel Processing

With our all-inclusive processing center for structural steel, we dramatically reduce the amount of manual labor normally required for sawing, drilling, tapping, plasma, and oxy fuel cutting by combining all these capabilities into one cell.

High-Value Metal Profiling Services

Our metal profiling value comes from deep integration that allows us to produce and finish complex assemblies in the same facility. Contact us to learn how we deliver this value to keep you on schedule and reduce costs.

Our Metal Profiling Benefits Add Up

Reduced Waste

More Options

Lower Costs

Faster Timelines

See What's Possible

Choose Standard Iron

OEMs choose Standard Iron for more than just outstanding parts. For 90+ years, we have been a source of strength in customer supply chains and a seamless extension of their assembly operation. Learn more or start your quote today.