Metal Engineering Powered by Integration

Our design, applications, and tooling engineers can work with any design files and multiple 3D CAD file formats to improve design and manufacturability. Our established partnerships with tooling shops across North America give us the ability to find you the lowest cost and the fastest lead time on every tooling project.

Here’s how our metal engineering services add value to every step of product development:

- Experts in SolidWorks, Pro-E, Autocad, Inventor, and Tekla BIM software

- $200+ million of CapEx invested in deeply-integrated manufacturing capabilities and quality systems

- In-house expertise in metal profiling, forming, welding, machining, assembly, and finishing

- Model sharing systems allow us to work with multiple file formats: dxf, iges, step, sldprt, prt, etc.

Our Metal Engineering Capabilities

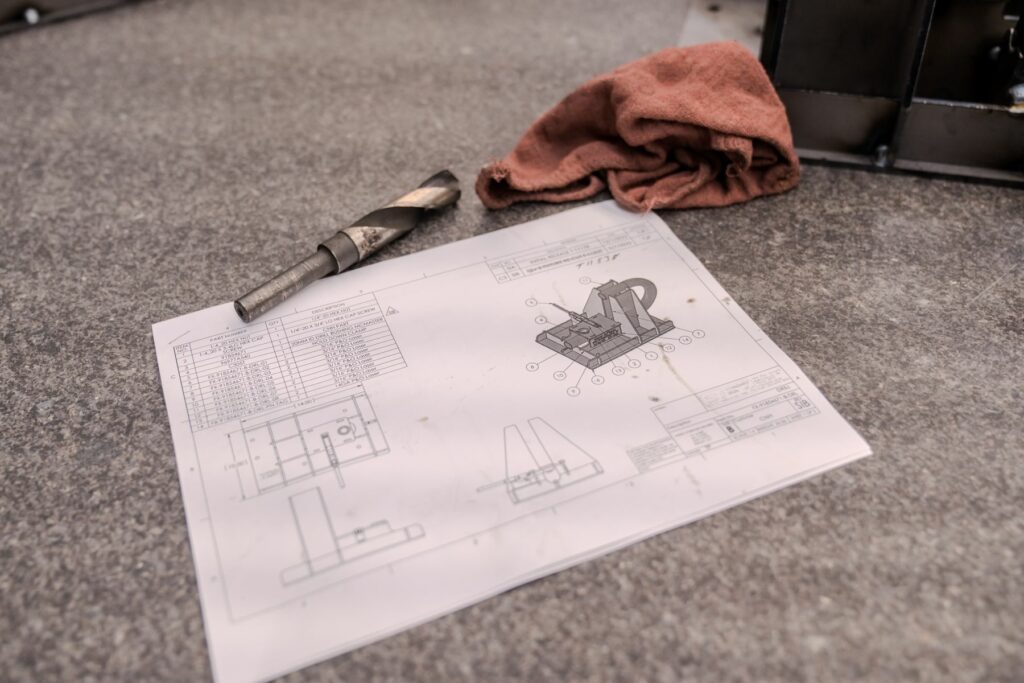

The Design

Even the simplest tooling design presents an opportunity for cost savings. Our specialty is selecting the best combination of materials, technology, and metal fabrication techniques to meet your design specifications while also saving you money.

The Application

Our engineering services meet a wide variety of OEM applications, from simple brackets to more complex spreader weld assemblies. We have built a global reputation for design and tooling expertise that reduces manufacturing cost while ensuring quality.

The Tooling

We are an industry leader with more than 700,000 square feet of in-house manufacturing capabilities, including an extensive tooling footprint backed by strong partnerships to ensure you get the lowest cost and the fastest lead times possible.

The Metal Engineering Partner to Lean On

Our metal engineering services offer the most value during the early stages of contract manufacturing. Contact us to learn how we can work as your partner to increase part performance and reduce tooling costs.

Our Metal Engineering Benefits Add Up

Reduced Waste

More Value

Better Performance

Faster Timelines

See What's Possible

Choose Standard Iron

OEMs choose Standard Iron for more than just outstanding parts. For 90+ years, we have been a source of strength in customer supply chains and a seamless extension of their assembly operation. Learn more or start your quote today.