Metal Forming Experience Matters

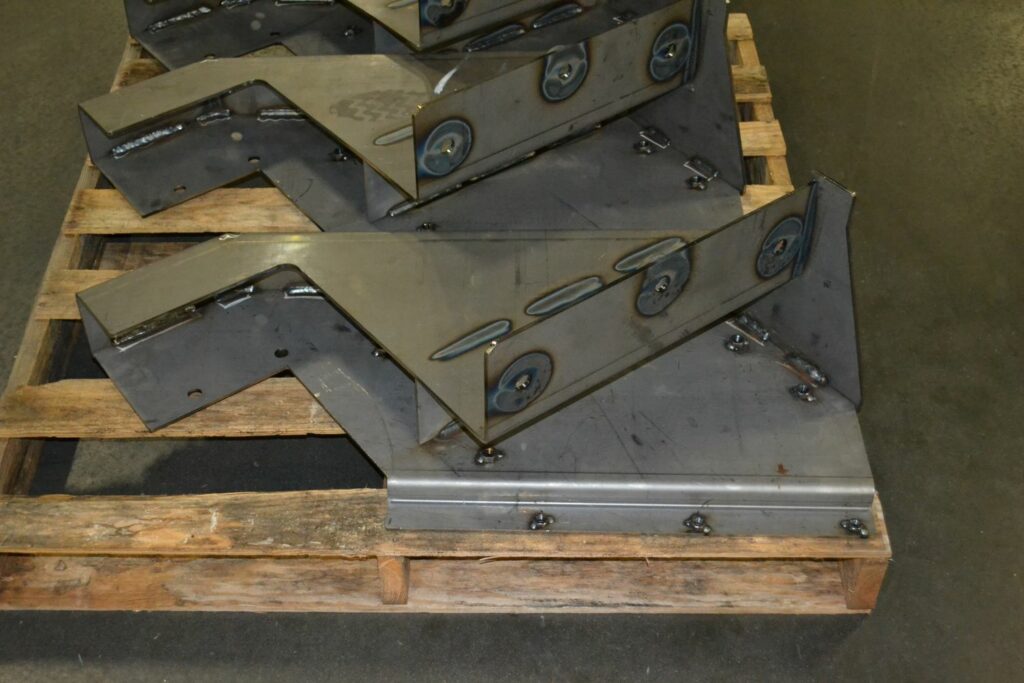

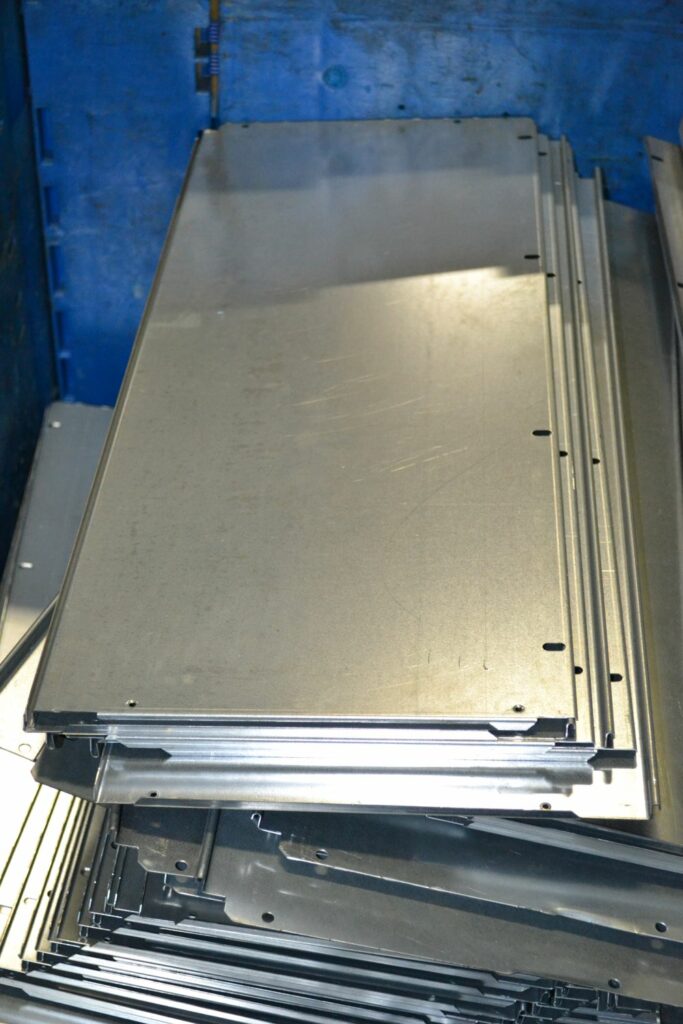

The experience is what makes our metal forming valuable. We have the deep industry, engineering, tooling, and manufacturing expertise to achieve desired tolerances and dimensions on larger frames, as well as chassis-type components, welded tube assemblies, and much more.

To support this, we have made continued investments in new metal forming equipment and facility expansion, including:

- Amada HG 2204 ATC auto tool change/240-ton press brake

- 700,000-plus square feet of forming and manufacturing capacity

- 5 Safan Darley electric press brakes with 35 to 143 tons range

- 8 CNC tube benders to form up to 4” (97.6mm) O.D. tubing

Our Metal Forming Capabilities

Press Brakes

Standard Iron’s 34 press brakes and robotic automation deliver a maximum 485 tonnage and a maximum length of 14’ (4.2m). Metal forming features include CNC back gauging and auto crowning, as well as auto laser gauging and off-line CNC programming.

Tube Bending

Our Axis and Horns 65TBRE CNC tube benders and automated saws allow us to produce high-quality parts with precision. Our capabilities include tube bending and plate rolling, with the ability to fabricate tubes and pipes up to up to 4” (97.6mm).

Forming Stamping Presses

Our 15 metal forming stamping presses pack a maximum punching force of 800 tons, with bed sizes up to 5’ x 8’ (1.5m x 2.4m). With Servo coil feed capabilities, our stamping presses are ideal for speeding timelines for repeatable and high-volume orders.

Your Experienced Metal Forming Partner

Our metal forming services are backed by more than 90 years of quality fabrication experience across key industries. Contact us to learn how we can leverage this value to improve results, increase speed, and reduce costs.

Our Metal Forming Benefits Add Up

Higher Standards

More Options

Better R&D

Faster Timelines

See What's Possible

Choose Standard Iron

OEMs choose Standard Iron for more than just outstanding parts. For 90+ years, we have been a source of strength in customer supply chains and a seamless extension of their assembly operation. Learn more or start your quote today.